AI Agents for Automotive Manufacturing

Predict failures, cut changeover losses, and improve first‑time quality across assembly, robotics, and paint with autonomous maintenance copilots.

Critical Assets

Where our agents make the biggest impact

Assembly Lines

Conveyors, stations, and tooling orchestrated for takt. Agents watch for bottlenecks, cycle drift, and equipment degradation across the full line.

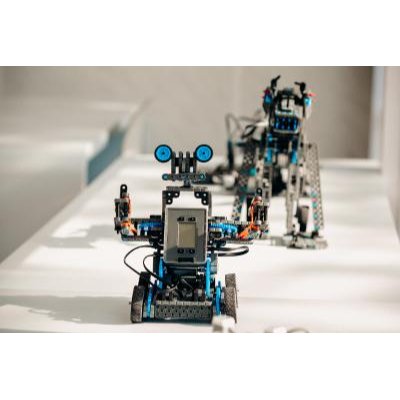

Robotic Systems

Welding and painting robots operating at high speed and precision. Agents track joint torque, path accuracy, and calibration windows to prevent quality escapes.

Stamping & Forming

High-tonnage presses and forming dies under extreme mechanical stress. Agents monitor press health, die wear, and lubrication anomalies to flag issues early.

Top Maintenance Challenges

Catastrophic Downtime Costs

Automotive production lines operate on just-in-time schedules where any equipment failure cascades across the supply chain. A single unplanned stoppage on a high-volume line can halt downstream assembly and delay deliveries.

Skilled Labor Shortage

The majority of automotive maintenance leaders identify skilled labor shortage as their leading challenge. Technicians who understood legacy stamping presses and paint booth robotics are retiring faster than replacements can be trained.

Complex Multi-Line Dependencies

Modern automotive plants run interconnected body, paint, and assembly lines. A failure in one line creates cascading bottlenecks. Diagnosing root cause across these interdependent systems requires deep institutional knowledge.

What Our AI Agents Do

Predictive & Condition Monitoring

Detect bearing wear, vibration spikes, thermal anomalies, and lubrication issues; generate work orders with probable root causes.

- Robot joint torque and cycle drift alerts

- Press stroke/vibration envelope breaches

- Paint booth temp/RH window monitoring

JIT Maintenance & Changeover Assist

Schedule tasks into natural breaks; retrieve validated SOPs, and verify calibration post-changeover.

- Automatic windowing to takt buffers

- Digital checks for PLC/robot version parity

- One‑point lessons tied to recent issues